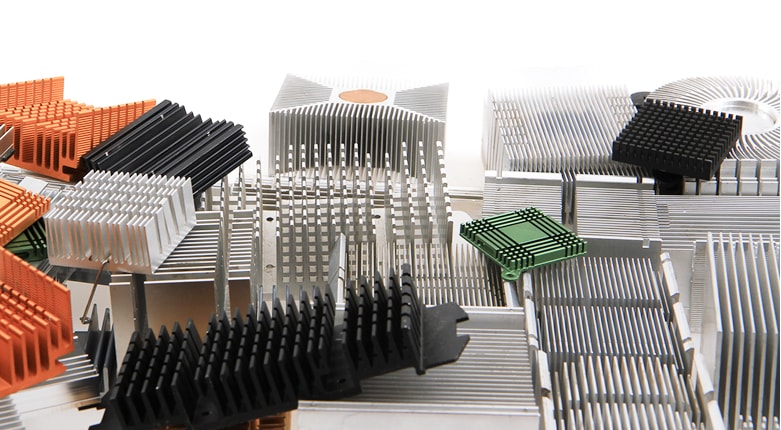

Thermal Management Heat Sinks

Critical Structures, Supporting Every Reliable Drive

We specialize in the manufacturing of core structural components for thermal management radiators. Our flagship products include:

Thermal Substrate

Heat Sink

Radiator connection plates are used to secure and stabilize the radiator, ensuring structural integrity, while heat dissipation fins help cool critical components and prevent high-temperature failures. Working in synergy, they ensure reliable vehicle operation.

Core Components for Automotive Heat Dissipation Systems

Precision Engineering Empowers Stable Performance

Core components for automotive heat dissipation systems are crucial for ensuring reliable vehicle operation under high-temperature conditions. They rely on precision manufacturing processes to achieve efficient heat dissipation and stable connections.

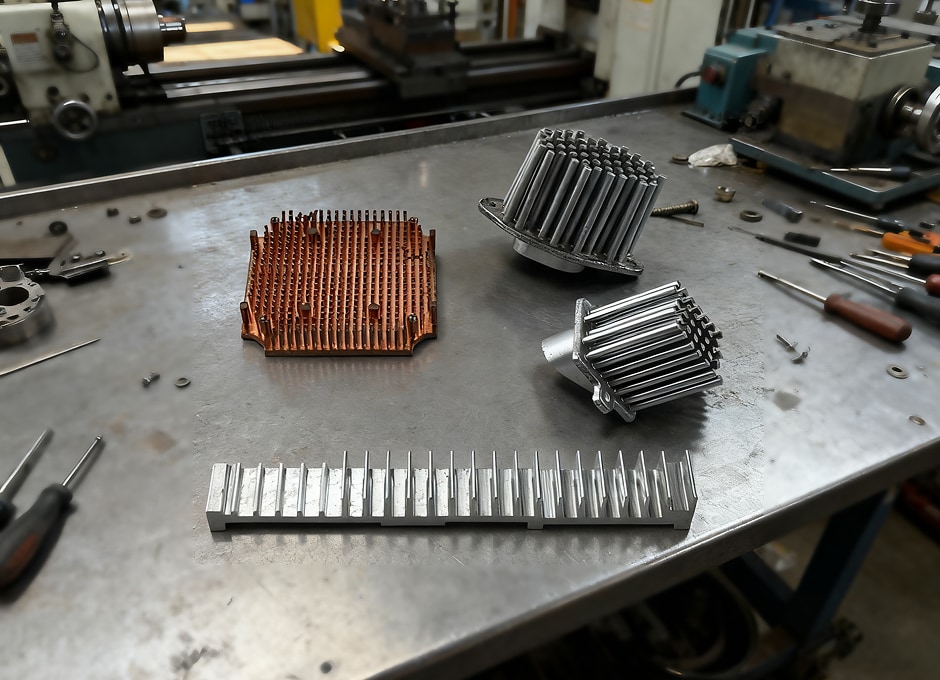

Thermal Substrate

ADAS Radar Thermal Substrate

Thermal Substrate

Heat Sink

Heat Sink

Heat Sink

Our one-stop production capability enables comprehensive optimization in efficiency and product stability, resulting in higher customer satisfaction.

Supplying Global Automakers

进入国际车厂平台,稳定量产供货中

力野的减震器安装上盖与空气悬架筒体,已广泛应用于中高端乘用车与新能源平台,具备高度结构与性能要求的应用条件。

- 减震器安装上盖:已通过 Ford 平台验证并稳定批量供货,充分体现了产品在全球项目中的可靠性表现。

- 空气悬架筒体:正与多家国际知名客户展开深度合作,持续拓展空气悬架系统结构件的应用布局。

Key Product Highlights

Thermal Substrate

Forming Process: Utilizes precision stamping technology to ensure a robust structure and a flat surface.

Core Function: Enables reliable installation between the radiator and the system, while ensuring efficient heat conduction.

Performance Advantages: Features vibration resistance and fatigue durability, ensuring long-term operational stability and safety of the components.

Heat Sink

Material & Manufacturing Process: Made from aerospace-grade aluminum alloy, using cold forging and extrusion stamping processes to increase fin density and expand the heat dissipation surface area.

- Core Role: Effectively controls the temperature of batteries, electric drives, and electronic equipment, ensuring system stability and driving safety under high-temperature operating conditions.

Looking for Solutions for Structural Components?

ASIC provides customized sample prototyping and technical consultation services upon request.

Contact us to learn more about our product specifications and application possibilities.