Precision Forging Technology

High Precision · High Stability

Meeting the Next-Generation Lightweight Structural Requirements

Continuously advancing process automation to proactively address future application needs.

Possess a complete set of 20 forging presses ranging from 50 tons to 2,500 tons

Capable of forging aluminum components weighing from 10 g to 6 kg

Cold forging dimensional tolerances can be stably controlled within ±0.07 mm

Hot forging dimensional tolerances can achieve a standard of ±0.10 mm

Efficient and Stable Processes

Meeting the Demands of Highly Complex Structural Components

ASIC’s precision machining process covers roughing, finishing, drilling, tapping, and pre-surface treatment, with highly stable and automated production.

For high-precision components, dedicated process optimization mechanisms and fixture teams ensure tolerances, shapes, and quality meet the strictest standards.

Multi-axis machining centers + automatic tool changers to improve machining efficiency

Process simulation and pre-designed fixtures to enhance prototyping success rate

Supports custom geometry machining (e.g., hollow structures, thin-walled parts)

Precision inspection and parameter feedback systems to ensure batch consistency

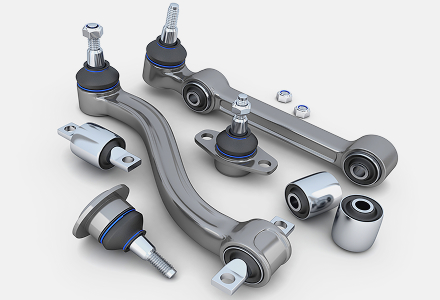

Application Areas

Precision Machining for Diverse Key Structural Components

Technology is widely applied in automotive chassis systems, suspension structures, humanoid robot linkages, energy equipment brackets, and high-strength housings, especially for components requiring high strength, lightweight design, and precision.

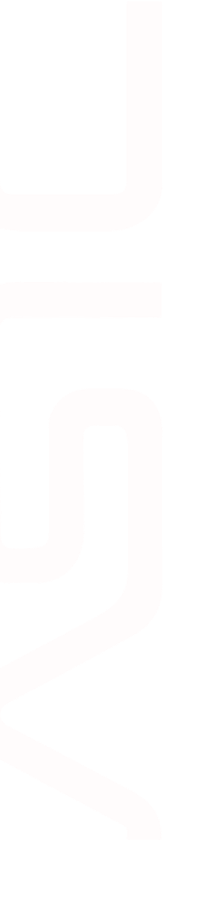

Automotive Chassis Shock Absorber Aluminum Forgings

Lightweight aluminum forgings with structural strength, elastic damping, and noise reduction

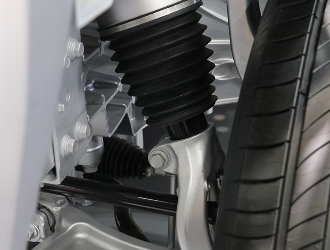

Humanoid Robot Frames, Joints, and Structures

Aluminum forgings providing lightweight design, reinforced structure, modular versatility, and vibration damping

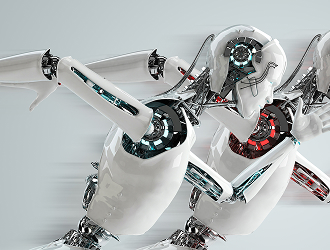

Aluminum Forged Heat Sinks

Lightweight aluminum forged heat sinks with thermal conductivity up to 160–200 W/m·K, outperforming cast aluminum and replacing high-cost copper alloys

Aerospace Drone Structures

Aluminum forgings enhance lightweight performance, energy efficiency, vibration damping, and modular versatility

Technical Cases

Adopted by Multiple International Brands, Proven High Quality

TESLA Vibration Damper System Components

Precision improved from ±0.03 mm to ±0.01 mm, reducing assembly errors

Porsche Air Suspension Components

Finished product yield increased by 22%, significantly shortening mass production cycle

BOSCH High-Pressure Fuel System Aluminum Housing

Achieved high consistency in internal diameter machining, passing internal airtightness standards

Porsche Air Suspension Components

Finished product yield increased by 22%, significantly shortening mass production cycle

Porsche Air Suspension Components

Finished product yield increased by 22%, significantly shortening mass production cycle

Porsche Air Suspension Components

Finished product yield increased by 22%, significantly shortening mass production cycle

Curious whether this technology fits your product?

We can provide sample analysis, prototyping, and technical consultation according to your needs.