About ASIC

Quality · Integrity · Efficiency

Alloy Seiko Industry Co., Ltd. (ASIC) was founded in 1995 in Taiwan.

At a time when China’s aluminum alloy precision forging industry was still in its infancy, ASIC had already established its manufacturing base in Guangdong Province—emerging an early leader in the field.

For over two decades, we have provided precision OEM manufacturing services to clients across the Taiwan Strait.Our factories, located in Shenzhen, Guangdong and Taizhou, Jiangsu, serve the automotive, aerospace, electrical, and recreational industries worldwide.

Guide by quality, integrity, and efficiency we we provide comprehensive aluminum alloy component manufacturing solutions.

Committed to Becoming the Most Valuable Lightweight Alloy Component Supplier

For years, ASIC has relied on its precision forging technology and advanced machining capabilities to provide OEM metal components for many world-renowned clients.

In ASIC’s quality philosophy, there is no best—only better through continuous improvement.

Leveraging a full quality management system and precise testing equipment, we deliver top-quality service to our customers.

Deep Integration, Expanded Applications

To provide more complete product services and explore new application areas, Alloy Seiko Industry Co., Ltd. joined Fusheng Precision Group in August 2024.

Leveraging Fusheng’s extensive expertise in material development, manufacturing technology, automation/intelligent systems, international management, and financial strength.

ASIC will advance from its current position as a component supplier toward critical sub-assembly and assembly systems—and expand into new fields such as aerospace and medical technology.

of Professional Experience

Patent Technologies

Annual Total Production Capacity

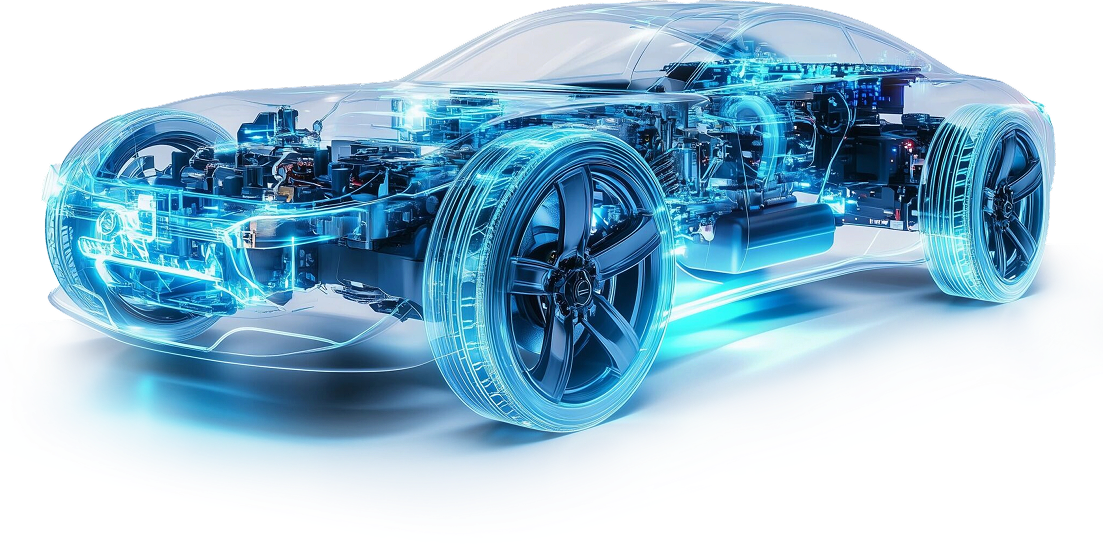

Automotive Light weighting

A Benchmark in Aluminum Alloy Component Manufacturing

Professional Recognitions

- Top 10 Enterprises in Precision Forged One-Piece Automotive Metal Parts

National High-Tech Enterprise

First Batch of City-Level Green Factories

National “Specialized, Refined, Distinctive, and Innovative Little Giant” Enterprise

Certified under ISO 9001, IATF 16949, ISO 45001, and ISO 14001

Dual Integration of IT & Industrialization Certification

The Choice of World-Class Brands

世界级品牌的共同选择

30年来,力野以稳定的品质、弹性的生产能力与可靠的交付效率,成为多家世界级品牌的长期合作伙伴。我们相信,数据背后是实力的见证,更是客户信赖的根本。

One-Stop Manufacturing Advantage

Fully Integrated Processes, Flexible Response to Every Need

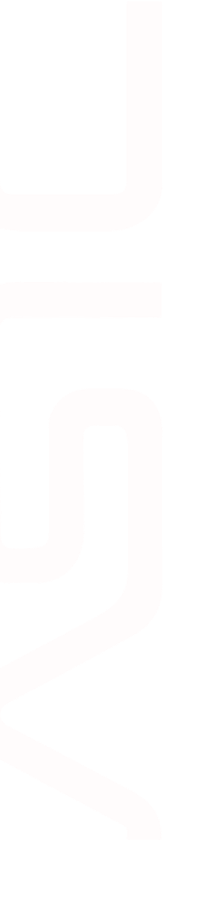

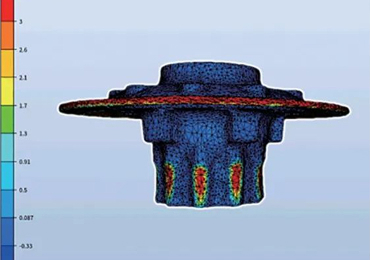

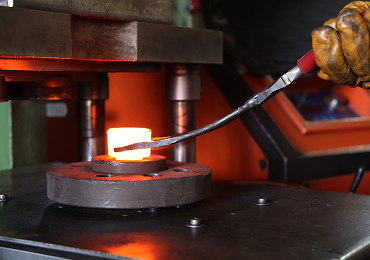

ASIC’s strength lies in its ability to provide a complete manufacturing service chain—from mold design and production, forging, heat treatment, machining, to inspection—all managed in-house.

This ensures both quality and efficiency, saving customers the time and cost of coordinating multiple suppliers.

With our flexible production system and rapid prototyping capability, we can quickly respond to customer needs from the earliest development stages—building trust and accelerating project timelines.

A Reliable Partner for the Manufacturing Industry

Quality × Supply × Service

Comprehensive support to ensure stable project progress.

ASIC company, through quality control, supply chain services, and technical support, has become a trusted partner of globally clients.

Quality Control

First Article & In-Process Inspections

Performance Testing

SPC / CPK Statistical Monitoring

Precision Testing Equipment

- In-Line Key Dimension SPC Control

100% Final Inspection for Critical Dimensions

Supply Stability Strategy

Through a dual procurement network covering both the Yangtze River Delta and Pearl River Delta, combined with forecast-based purchasing and bi-monthly coordination meetings,ASIC effectively reduces risks related to raw material fluctuations and delivery delays—ensuring greater order security for customers.

Technical & Service Support

Whether in project initiation or mass production, the Liyeno team provides expert recommendations and rapid assistance.With transparent communication and progress management across the entire process, we help customers reduce project risk and improve overall efficiency.

Upgrade · Expansion · Breakthrough

From Process Innovation to Market Expansion—Driving Continuous Product Evolution

ASIC is actively investing in the process innovation of aluminum alloy components such as shock absorber housing, pulleys, and camera housings,

developing automated forging and intelligent manufacturing systems, and continuously optimizing existing processes to enhance performance and production efficiency.

In the next five years, we will focus on three core directions:

Automotive Structural Components, Lightweight Design, and Next-Generation Components,

while expanding into emerging sectors such as robotics and new energy vehicles.

Through continuous R&D and process upgrades, ASIC aims to become synonymous with aluminum alloy technology.

Balancing Technology and Responsibility, Moving Toward a Sustainable Future

As we move toward our next five-year goals, ASIC integrates sustainability principles, optimizing material utilization, reducing process carbon emissions, and establishing an initial ESG management framework.

We firmly believe that technological advancement and corporate responsibility can progress together, creating lasting value for customers, society, and the environment.

Corporate Responsibility

Sustainable Operation

Pursue both technological innovation and quality objectives, delivering zero-defect products to customers.

Our Milestones

Founded Alloy Seiko Precision Co., Ltd. in Taichung, Taiwan.

Established Alloy Seiko (Shenzhen) Co., Ltd. (ASIC) in Shenzhen, Guangdong.

Began supplying door hinges for Chrysler.

Became an approved supplier to Brembo, entered motorcycle parts manufacturing, and supplied to BMW and Harley-Davidson.

Taizhou plant began mass production; certified as a National High-Tech Enterprise.

Received “Dual Integration of IT & Industrialization” certification from the Ministry of Industry and Information Technology.

Fusheng Precision Group invested in Alloy Seiko; Guangsheng in Zhongshan became the largest shareholder.

Began industrial transformation and upgraded to ISO 9001/TS 16949 quality management system.

Certified under ISO/TS 16949 and passed ISO 9001:2000 re-audit.

Became an approved supplier to Bosch, supplying components to Bosch Rexroth.

Became an approved supplier to Continental Group; established Jiangsu Alloy Seiko (Taizhou) Co., Ltd. (ASTC)

Adjusted production layout to focus on lightweight and new energy automotive parts.