Technologies

Full-Process Control for High-Precision Lightweight Solutions

ASIC Precision focuses on aluminum alloy and light metal process integration, providing one-stop services from forging and machining to surface treatment. We help customers develop product solutions that combine high precision, lightweight design, and stable delivery — widely applied in industries such as automotive, robotics, and energy equipment.

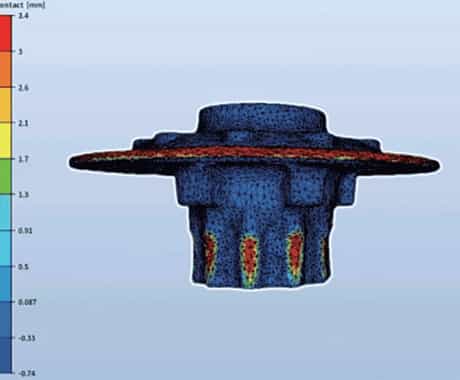

Aluminum Forging Mold R&D and Design

During mold design, professional 3D finite element forging simulation software is applied to enhance the efficiency of the forging process.

Precision Forging Technology

By integrating cold and hot forging techniques and combining them with in-house mold systems, we significantly improve forming consistency and production efficiency to meet the strength and lightweight requirements of aluminum alloy components.

Precision Machining

Multi-axis CNC machining combined with intelligent scheduling systems achieves ±0.006 mm cutting precision, ensuring both machining efficiency and stability — ideal for complex structures or high-precision component requirements.

Focusing on Future Technology Innovation

Continuously advancing automation in manufacturing processes to meet future application demands.

1

Intelligent forging production lines

2

Automated loading/unloading and scheduling systems

3

Smart suspension and autonomous driving systems

4

Material innovation (composite materials and lightweight structures)

From Mold to Mass Production — Optimized Process Solutions

Covering forging, machining, surface treatment, and quality control, ASIC offers a fully integrated process from mold design and forming simulation to final product delivery — accelerating development efficiency and improving mass production stability.

Mold Design and Machining

1.Forging molds

2.Stamping molds

3.Progressive forging-stamping molds

Forging

1.Hot forging

2.Cold forging

3.3D forging

Stamping press

1.Single press

2.Continuous press

3.Combined press-forging

Machining

1.CNC turning

2.CNC milling (3-axis / 4-axis / 5-axis)

3.Turn-mill compound machining

Heat Treatment

1.T2 (annealing)

2.T4 (quenching)

3.T6 (artificial aging)

Surface Treatment

1.Tumbling / phosphate coating

2.blasting / shot peening

3.Anodizing

4.Polishing / brushing

Building Predictable Process Quality

Continuously deepening process automation to anticipate future application needs.

- SPC in-line statistical control

- 100% FQC inspection on key dimensions

- ISO / IATF certified quality system

- Precision inspection equipment and full traceability

- Independent laboratory

- MES manufacturing management system

- Supplier management and process control